- Products

Power Transmission Components

All Products

-

Ball Transfer Units

All Products

Air Cargo Ball Transfer Series SPC

Air Cargo Ball Transfer Series SPC

Customized Machined Metal Ball Transfer Series

Customized Machined Metal Ball Transfer Series

Disk Mount Ball Transfer Series

Disk Mount Ball Transfer Series

External Spring Loaded Ball Transfer Series

External Spring Loaded Ball Transfer Series

Flange Mount Ball Transfer Series

Flange Mount Ball Transfer Series

Internal Spring Loaded Ball Transfer Series

Internal Spring Loaded Ball Transfer Series

Machined Bolt Fitted Ball Transfer Series

Machined Bolt Fitted Ball Transfer Series

Machined Press Fit Ball Transfer Series

Machined Press Fit Ball Transfer Series

Plastic Ball Transfer Series

Plastic Ball Transfer Series

- About Us

- Rescources

- Industries

- News

- Contact Us

Deep Groove Ball Bearings

Deep Groove Ball Bearings Self-aligning Ball Bearings

Self-aligning Ball Bearings Angular Contact Ball Bearings

Angular Contact Ball Bearings Hybrid Ceramic Bearings

Hybrid Ceramic Bearings Magneto Bearings

Magneto Bearings Plastic Ball Bearings

Plastic Ball Bearings Needle Roller Bearings

Needle Roller Bearings Spherical Roller Bearings

Spherical Roller Bearings Cylindrical Roller Bearings

Cylindrical Roller Bearings Tapered Roller Bearings

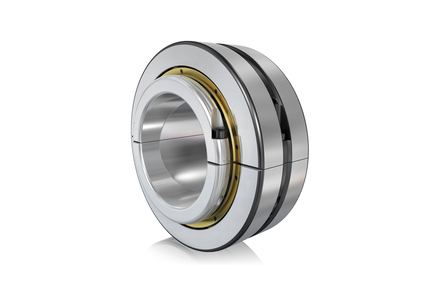

Tapered Roller Bearings Split Roller Bearings

Split Roller Bearings CARB Toroidal Roller Bearings

CARB Toroidal Roller Bearings Thrust Ball Bearings

Thrust Ball Bearings Axial Needle Roller Thrust Bearings

Axial Needle Roller Thrust Bearings Cylindrical Roller Thrust Bearings

Cylindrical Roller Thrust Bearings Spherical Roller Thrust Bearings

Spherical Roller Thrust Bearings Tapered Roller Thrust Bearings

Tapered Roller Thrust Bearings Angular Contact Thrust Ball Bearings

Angular Contact Thrust Ball Bearings Spindle Bearings

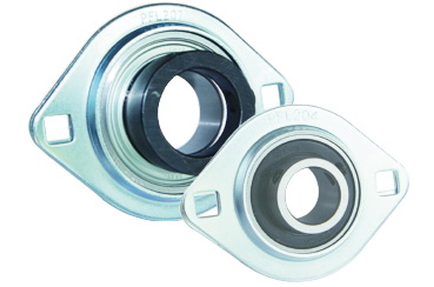

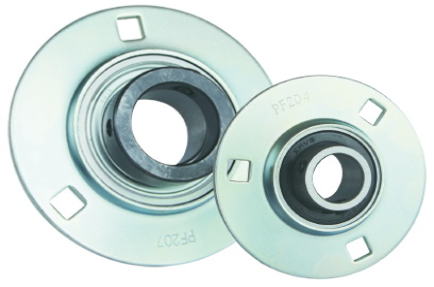

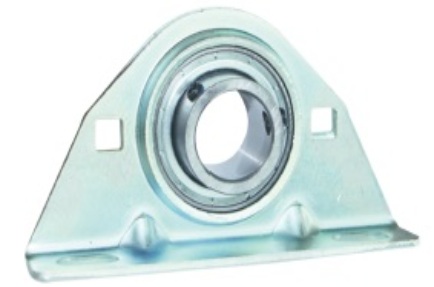

Spindle Bearings SBPSD200 SAPSD200-Metric Size

SBPSD200 SAPSD200-Metric Size SBPSD200 SAPSD200-Inch Size

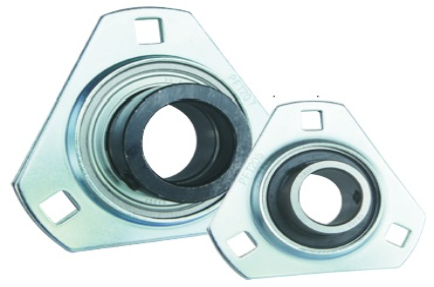

SBPSD200 SAPSD200-Inch Size SBFTD200 SAFTD200-Metric Size

SBFTD200 SAFTD200-Metric Size SBFTD200 SAFTD200-Inch Size

SBFTD200 SAFTD200-Inch Size SBTRD200 SATRD200-Metric Size

SBTRD200 SATRD200-Metric Size SBTRD200 SATRD200-Inch Size

SBTRD200 SATRD200-Inch Size SBPP200 SAPP200-Metric Size

SBPP200 SAPP200-Metric Size SBPP200 SAPP200-Inch Size

SBPP200 SAPP200-Inch Size SBPFL200 SAPFL200-Metric Size

SBPFL200 SAPFL200-Metric Size SBPFL200 SAPFL200-Inch Size

SBPFL200 SAPFL200-Inch Size SBPF200 SAPF200-Metric Size

SBPF200 SAPF200-Metric Size SBPF200 SAPF200-Inch Size

SBPF200 SAPF200-Inch Size SBPFT200 SAPFT200-Metric Size

SBPFT200 SAPFT200-Metric Size SBPFT200 SAPFT200-Inch Size

SBPFT200 SAPFT200-Inch Size SBPBS200 SAPBS200-Metric Size

SBPBS200 SAPBS200-Metric Size RCSM RCSMS LRCSM-Metric Size

RCSM RCSMS LRCSM-Metric Size RCSM RCSMS LRCSM-Inch Size

RCSM RCSMS LRCSM-Inch Size RCR LRCR-Metric Size

RCR LRCR-Metric Size RCR LRCR-Inch Size

RCR LRCR-Inch Size CR LCR-Metric Size

CR LCR-Metric Size CR LCR-Inch Size

CR LCR-Inch Size SBR200 SAR200-Metric Size

SBR200 SAR200-Metric Size SBR200 SAR200-Inch Size

SBR200 SAR200-Inch Size SBRPP200 SARPP200-Metric Size

SBRPP200 SARPP200-Metric Size SUCSP200-Metric Size

SUCSP200-Metric Size SUCSP200-Inch Size

SUCSP200-Inch Size SUCSF200-Metric Size

SUCSF200-Metric Size SUCSF200-Inch Size

SUCSF200-Inch Size SUCSFL200-Metric Size

SUCSFL200-Metric Size SUCSFL200-Inch Size

SUCSFL200-Inch Size SUCST200-Metric Size

SUCST200-Metric Size SUCST200-Inch Size

SUCST200-Inch Size SUCSTRS200-Metric Size

SUCSTRS200-Metric Size UP000

UP000 UFL000

UFL000 KP000

KP000 KFL000

KFL000 U000

U000 K000

K000 SSUP000

SSUP000 SSUFL000

SSUFL000 SSKP000

SSKP000 SSKFL000

SSKFL000 SU000

SU000 SK000

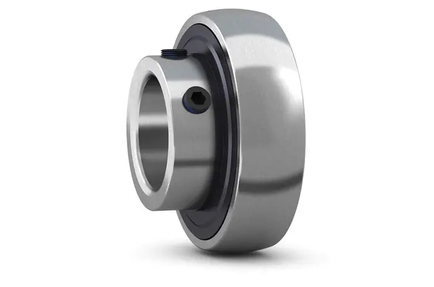

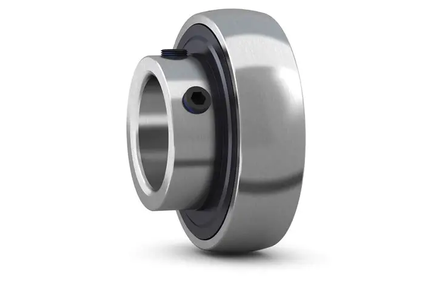

SK000 UC200-Metric Size

UC200-Metric Size UC200-Inch Size

UC200-Inch Size UCX00-Metric Size

UCX00-Metric Size UCX00-Inch Size

UCX00-Inch Size UC300-Metric Size

UC300-Metric Size UC300-Inch Size

UC300-Inch Size HC200-Metric Size

HC200-Metric Size HC200-Inch Size

HC200-Inch Size HC300-Metric Size

HC300-Metric Size SN500 SSN500

SN500 SSN500 SN600 SSN600

SN600 SSN600 SN200

SN200 SN300

SN300 SNU500

SNU500 SNG500

SNG500 SN3000 SN3100

SN3000 SN3100 S3000K

S3000K SD500 SD600

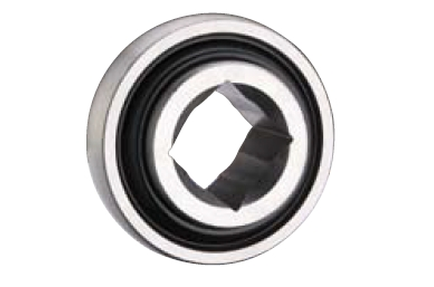

SD500 SD600 Round Bore Non-Relubriaable

Round Bore Non-Relubriaable Square Bore Non-Relubricable

Square Bore Non-Relubricable Round&Square Bore Non-Relubrica

Round&Square Bore Non-Relubrica Round Bore Relubricable

Round Bore Relubricable Square Bore Relubricable

Square Bore Relubricable Hex Bore Series-1

Hex Bore Series-1 Hex Bore Series-2

Hex Bore Series-2 200 Series-1

200 Series-1 200 Series-2

200 Series-2 Radial Spherical Plain Bearings

Radial Spherical Plain Bearings Angular Contact Plain Bearings

Angular Contact Plain Bearings Thrust Plain Bearings

Thrust Plain Bearings Stainless Steel Plain Bearings

Stainless Steel Plain Bearings Precision Ground Sphercial Plain Bearings

Precision Ground Sphercial Plain Bearings High Speed Spherical Plain Bearings

High Speed Spherical Plain Bearings Standard Rod Ends

Standard Rod Ends Hydraulic Cylinder Rod Ends

Hydraulic Cylinder Rod Ends Ball Joints

Ball Joints Stainless Steel Rod Ends

Stainless Steel Rod Ends Injection Molded Rod Ends

Injection Molded Rod Ends Plastic Rod Ends

Plastic Rod Ends Aluminum Rod Ends

Aluminum Rod Ends High Speed Rod Ends

High Speed Rod Ends Clevises

Clevises Linear Ball Bushings

Linear Ball Bushings Flanged Linear Ball Bushings

Flanged Linear Ball Bushings Linear Slide Units

Linear Slide Units Linear LM Shafts

Linear LM Shafts Linear Shaft Supports

Linear Shaft Supports Ball Screws

Ball Screws Ball Screw Supports

Ball Screw Supports PA Angular Contant Ball

PA Angular Contant Ball PR Radial Contant Ball

PR Radial Contant Ball PX4-point Contant Ball

PX4-point Contant Ball PR Seald Radial Contant Ball

PR Seald Radial Contant Ball Metric P Series Bearing

Metric P Series Bearing Metric PB Series Bearing

Metric PB Series Bearing Special Water Pump Bearings

Special Water Pump Bearings W..S

W..S W

W WB

WB WK

WK WKN

WKN WN..S

WN..S WN

WN WNS

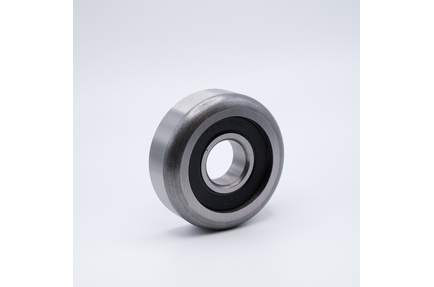

WNS Mast Guide Bearings

Mast Guide Bearings Metric Size Adapter Sleeves

Metric Size Adapter Sleeves Inch Size Adapter Sleeves

Inch Size Adapter Sleeves Withdrawal Sleeves

Withdrawal Sleeves Lock Nuts

Lock Nuts Lock Washers

Lock Washers Lock Clip and Lock Plate

Lock Clip and Lock Plate Driving Chains

Driving Chains Conveyor Chains

Conveyor Chains Engineering Chains

Engineering Chains Leaf Chains & Hoisting Chains

Leaf Chains & Hoisting Chains Agricultural Chains

Agricultural Chains Stainless Steel Chains

Stainless Steel Chains Taper bushings

Taper bushings Weld-on hubs

Weld-on hubs Bolt-on hubs

Bolt-on hubs Adapters

Adapters QD Bushings

QD Bushings QD Weld-on hubs

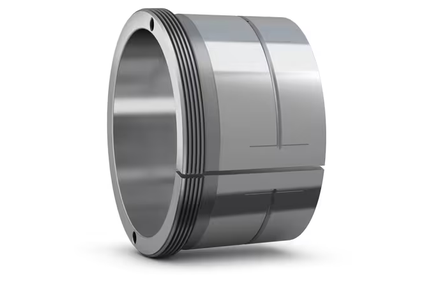

QD Weld-on hubs Mechanical Locking Bushes

Mechanical Locking Bushes Elastomeric Couplings

Elastomeric Couplings Steel Couplings

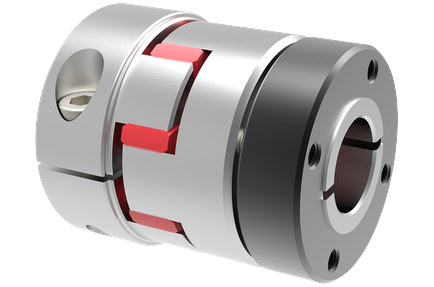

Steel Couplings Zero Backlash Couplings

Zero Backlash Couplings Universal Joints

Universal Joints Rigid Couplings

Rigid Couplings Fluidomat Couplings

Fluidomat Couplings 2A Type

2A Type Engineering Plastic

Engineering Plastic Hardened Teeth

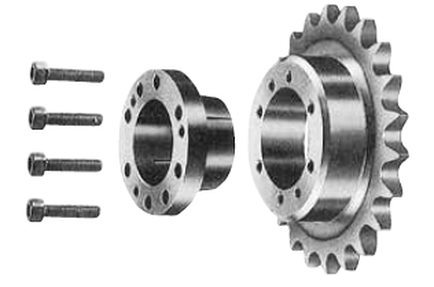

Hardened Teeth Lock Sprocket N Type

Lock Sprocket N Type Lock Sprocket S TypeC

Lock Sprocket S TypeC RS Roller Chain BS-DIN Sprockets

RS Roller Chain BS-DIN Sprockets Single Dual

Single Dual Stainless Steel

Stainless Steel Standard Pilot Bore

Standard Pilot Bore Classical Timing Belts

Classical Timing Belts HTD Timing Belts

HTD Timing Belts Giga Torque GX Timing Belts

Giga Torque GX Timing Belts Metric Timing Belts

Metric Timing Belts Timing Belt Clamping Plates

Timing Belt Clamping Plates Classical Timing Pulleys

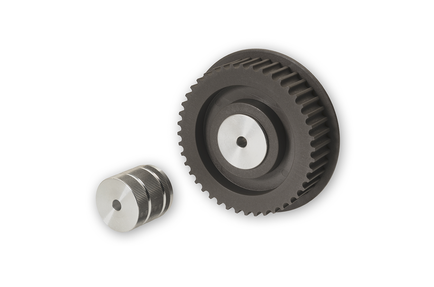

Classical Timing Pulleys HTD Timing Pulleys

HTD Timing Pulleys GTR Timing Pulleys

GTR Timing Pulleys Metric Timing Pulleys

Metric Timing Pulleys V-Belt Pulleys For SPZ

V-Belt Pulleys For SPZ V-Belt Pulleys For SPA

V-Belt Pulleys For SPA V-Belt Pulleys For SPB

V-Belt Pulleys For SPB V-Belt Pulleys For SPC

V-Belt Pulleys For SPC English

English Chinese

Chinese Spanish

Spanish French

French Japanese

Japanese German

German Portugal

Portugal Russian

Russian Arabic

Arabic